Length Markings

Both coils and sticks have lengths marked in 5-foot increments, always starting from zero.

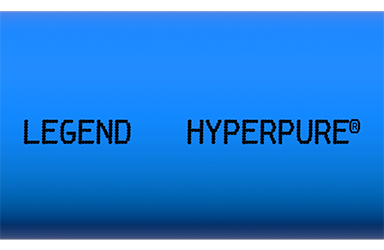

Product Branding

Both our company and brand names are printed on the tube.

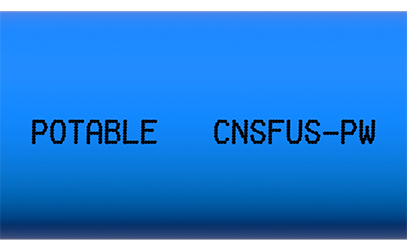

Potable cNSFus-pw

HyperPure is certified to NSF/ANSI 14 and NSF/ANSI/CAN 61 standards for plastic piping products used in potable water systems.

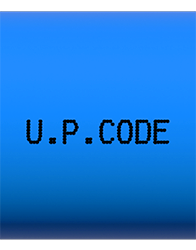

U.P. Code

Our tube is certified and listed to Uniform Plumbing Codes.

ASTM F2769

HyperPure meets and exceeds the requirements of ASTM F2769, the PE-RT performance equivalent of ASTM F876 and F877, which are used for PEX.

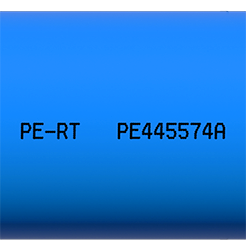

PE-RT PE445574A

This is the material cell designation code for PE-RT.

CSA-B137.18

HyperPure is certified to Canadian Standards for potable pressure pipe.

ICC-ES PMG-1363

Our tube is third-party certified by ICC-ES and listed to International Plumbing Code (IPC), International Residential Code (IRC), and Uniform Plumbing Code (UPC).

cETLus FS25/SD50

HyperPure is rated to perform better than the minimum flame and smoke spread requirements in both the U.S. and Canada.

ASTM E84

Our tube is also listed to ASTM E84 for surface burning and smoke density, a requirement for use in plenum installations.

CAN/ULC S102.2

HyperPure has been tested for compliance with CAN/ULC S102, the standard method for testing the surface-burning characteristics of building materials.

SDR-9 Wall Thickness

The measure of wall thickness value following pipe sizing standards.

CL5 Chlorine Resistance

HyperPure has level 5 chlorine resistance in continuous use at 140°F, per ASTM F2023.

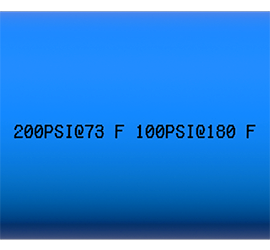

Operating Specifications

HyperPure is rated for operation at 200 PSI at 73° F and 100 PSI at 180° F.

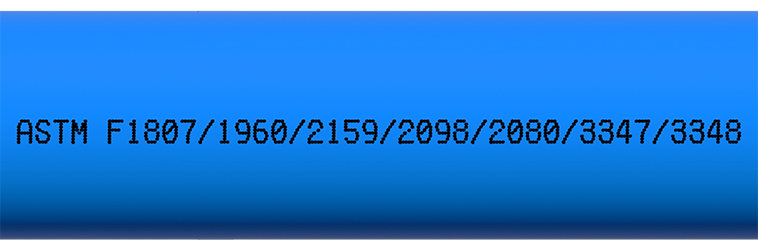

Fitting Compatibility

HyperPure is compatible with copper crimp, stainless steel cinch, cold expansion, stainless steel PEX press, insert, push-fit, and fusion fittings.

ASSE 1061

Our tube meets the ASSE standards for push-fit fittings.

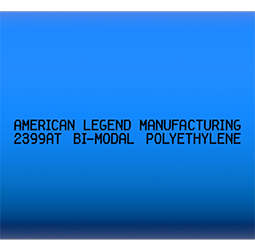

American Legend Manufacturing

HyperPure is manufactured by American Legend Manufacturing, a division of Legend Valve & Fitting Inc.

Made in USA

HyperPure is manufactured at our headquarters in Auburn Hills, Michigan.

CTS Diameter

The tube diameter is listed in nominal copper tube size.

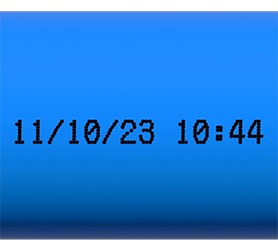

Manufacturing Timestamp

The print string also lists the date and time of manufacturing.

Notice of Recyclability

HyperPure is fully compliant with HDPE Code 2, allowing all scrap to be recycled.

Slide 1 of 21